1.0

Purpose

1.1 To evaluate, control and document the

deviations (and batch deviations, reprocessing for approval or rejection) to

ensure that product quality, safety, purity and efficacy is maintained and the activities are in accordance

with the frame work of cGMP. And It also ensures that the investigation (if required) is carried out,

recorded and any cause or causes identified and necessary corrective and

preventive measures are taken. If required to bring the deviation under the

notice of the concerned management of NAME Pharmaceuticals Ltd.

2.0

Scope

2.1 This SOP is applicable for all

products, chemicals & packaging materials, the processes, systems, equipment’s,

instrumentation, utilities and facilities used to produce and control them and

be followed by all departments of NAME Pharmaceuticals Ltd.

3.0

Responsibility

3.1 Head of Quality Assurance or His / Her

Nominee:

1. Review

deviations in relation to their impact on quality and GMP compliance.

2. Ensure

this procedure covers the initial identification, assessment, investigation (if

required), report preparation and remedial action proposal to prevent

recurrence.

3. Ensuring

that the system for investigation of failure and the effectiveness of

corrective actions is managed and monitored.

4. Review

of any Environmental, Health or Safety implications from the deviation.

5. Implement

decision regarding remedial action through change control (if required), if

required Regulatory for those

batch deviations having potential regulatory impact.

6.

Ensure the documentation of all deviation

records for the trend analysis of deviations.

3.2 Originator:

1. Ensuring

that the details, including any immediate action taken, of the occurrence of a

deviation are recorded at the time of the incident and any further action is

agreed with the Departmental Manager.

3.3 Departmental Manager / Head / In-Charge

1. Ensuring

that Head of Quality Assurance or His / Her Nominee are informed promptly and

that in conjunction with any / or other relevant function, assessing whether

there is impact on product quality and / or regulatory compliance. Ensuring

that any immediate actions taken are appropriate, discussing with the above and

the details of the occurrence has been reported.

2. Authorizing

any Corrective Actions and ensuring any Preventative Actions are identified and

completed against an agreed time scale.

3. Ensuring

that the deviation is logged, monitored and assessed and summaries provided.

3.4 Investigation Team

1. An investigation team should be constituted

comprising members from Quality Assurance / Control and Other Department(s)

depending on the nature of the deviation.

2. Ensuring

that an investigation is carried out, this will establish the cause (root

cause), scope and impact of the deviation.

3. Ensuring

that the investigation team comprises relevant experts.

4. Ensuring

that all aspects of investigation are carried out and reported to an agreed

time scale

5.

Ensuring that any actions required to prevent

recurrence are identified.

4.0 Abbreviations and Definitions

4.1 Deviation:

Any planned or unplanned event or failure from Standard Operating Procedure and or failure to meet specified limits. This may include, but is not limited to:

Ø Alert

/ Action Limits exceeded.

Ø Instrument

outside of its calibration date and / or tolerance.

Ø Environmental

results outside of specification.

Ø Deviation

from SOP or processing limits in manufacture or testing.

Ø Process,

equipment, procedure or system failure.

Ø Material

accountability discrepancy.

Ø Damage

in storage or handling.

Ø Out of

Specification result.

Ø Component

/ supplier problem

Ø Operator

errors.

Deviation must be recorded, investigated (if required), reported, and included in any monitoring / trending information; note that, product rejection may or may not result. The deviation can be classified as follow.

4.1.1. Critical Deviation

If the unplanned deviation that has anticipated

a serious impact on product quality which could cause either adverse health

consequence or regulatory impact and needs urgent attention of all departments

concerned, will investigate through investigation committee, prior to any

decision about release or reject.

4.1.2. Major

Deviation

The unplanned deviations that having an impact

on product quality and therefore need to be thoroughly evaluated and

investigated prior to any decision about release or reject through

investigation committee.

4.1.3. Minor Deviation

Minor deviations are those which are unplanned deviation, are not critical to product quality, need to be documented, reviewed and approved.

4.2 Fail / Reject

The status of a product or material, which has either directly or indirectly been the subject of a deviation / failure investigation, and the scientifically justified outcome of the investigation is that the product / material does not meet either its Quality specification(s), or comply with registered information.

4.3 Investigation

The systematic process by which the deviation and supporting evidence is examined to determine causal factors, the root cause, the impact on product / batch / material quality, established, corrective actions required determined, and a documented report generated.

4.4 Immediate Action

Actions taken at the time of an incident to make the process / product / system / material safe and secure, and / or prevent further deterioration.

4.5 Corrective Action

Remedial action taken at the time of the event or identified as part of the (root cause) investigation, that is necessary to recover the product / process / material / system, affected by the deviation.

4.6 Preventative Action

Actions identified as part of the (root cause) investigation, which must be carried out to prevent the Non-conformance recurring. Preventative actions may or may not be completed prior to a decision on batch disposition.

4.7 Reprocessing

The treatment of all or a part of a batch of

product of an unacceptable quality from a defined stage of production with the

original process so that its quality may be rendered acceptable by one or more

additional operations.

5.0 Materials and Equipment

5.1 None

6.0 Precaution / Health and Safety Considerations

6.1 None

7.0

Procedure

7.1 Numbering and Logging of Deviation

7.1.1 Record the deviation in details in the Deviation Logbook (Annexure-II) and update the records and maintain as the investigation proceeds. Details to be completed in the log include:

Ø Date

of occurrence

Ø Reference

number - Unique reference number (described in the following section 7.1.2)

Ø Product

/ Material / Equipment name

Ø Batch

/ Code / ID number of the corresponding above name

Ø A

single sentence summary statement of the details of the deviation

Ø Investigation

close out date (investigation is required or not) - Agreed time scale for

corrective

actions or investigation close out date.

Ø Further

investigation closed date – Date of confirmation of completion of corrective

actions

or further investigation closed date.

Ø Where

or not product failure is implicated.

Ø Close

out date of preventive actions - Agreed time scale for preventive actions

Ø Preventive

Actions closed date - Date of confirmation of completion of preventative action

Ø Final

close out date.

State N/A where any column is not required to fulfil.

7.1.2 Follow the unique reference number format as following:

D/DC/ XXX/YY

D = Deviation

DC = Department

Code

XXX = Three-digit

sequential number, commencing 001, taken as the next sequential number

from the logbook

YY = Last two digits of the current year.

Deviation Department

Codes (DC):

|

Department

Name |

Abbreviated

Department Code |

|

Quality

Assurance |

QA |

|

Quality

Control |

QC |

|

Microbiology |

MB |

|

Production |

PR |

|

Engineering |

EN |

|

Warehouse |

WH |

|

Product

Development |

PD |

7.2 Deviation Identification, Action Taken and Notification

7.2.1 When any deviation /incidents come to the notice of any personnel, the observer will immediately stop the operations and notify the incident to Head of concerned department, who discuss the matter with Head of Quality Assurance or His / Her Nominee.

7.2.2 Collect data / information pertaining to the deviation, and review the Departmental Manager, who will confirm the occurrence of the deviation.

7.2.3 Notify Head of Quality Assurance or His / Her Nominee regarding the deviation. Discuss the type of the deviation considering the impact on the product quality.

7.2.4 On agreement of the deviation, raise a Deviation Management Form (Annexure-III) with the next sequential unique reference number taken from the deviation logbook (Annexure-II)

7.2.5 Complete the Deviation Management form (Annexure-III).

7.2.6 Review and assess the type of the deviation weather the deviation is critical or major or minor type.

7.2.7 Minor deviations are needed to be documented, reviewed and approved by the Head of Quality Assurance or His / Her Nominee.

7.2.8 Investigate the major and critical type deviation prior to any decision about release. But if Head of Quality Assurance or His / Her Nominee decides to investigate the issue then the deviation will be investigated prior to any decision about release.

7.2.9 During investigation find out the root cause and also identify corrective and preventive actions necessary. If the root cause could not be identified then the investigation committee will decide the further action to be taken.

7.2.10 Take decision regarding the fate of the batch such as approval or rejection. If approved, take decision that additional testing, stability evaluation or validation or reprocessing is required or not.

7.2.11 Write the procedure for reprocessing of batches that do not conform to standards or specification. Get approval of the procedure of reprocessing from Head of Quality Assurance or His / Her Nominee and also follow change control procedure if the reprocessing steps are being permanent for the future.

7.2.12 Reprocessing procedure must define steps to be taken to ensure that the re-processed batches will conform with all established standards, specifications and characteristics and assess regarding process validation and stability implications.

7.2.13 Reprocessing of product is exceptional and must not be done on a routine basis.

7.2.14 Decide whether additional testing, stability evaluation of reprocessed batch is required or not and validation of the product is required or not.

7.2.15 Special consideration should be given for the need to revalidation.

7.2.16 Archive all records of reprocessing.

7.2.17 Raise change control if permanent change is required.

7.2.18 Keep the product of deviation and or for reprocessing in a separate area.

7.2.19 Evaluate and close out the deviation in a timely manner (normally within 30 calendar days).

7.2.20 Consider that the incomplete step (continuation of a process after an in-process control test) as a part of the normal process, not as reprocessing.

7.2.21 Document supplemental filing to allow for (planned) Reprocessing in the course of commercial Manufacturing, take approval by the Regulatory authority.

7.2.22 Give special consideration for the need to revalidate and for the need to perform additional stability studies.

7.3 Conduct Investigation

7.3.1 Appoint an investigation leader and the team to carry out investigation by Head of Quality Assurance or His / Her Nominee.

7.3.2 Complete the investigation in a timely manner. Carry out investigation on the basis / type of the deviation.

7.3.3 Generate a report on completion of the investigation, summarize the outcome, with respect to effect on quality, root cause of the incident, corrective and preventative actions.

7.3.4 The investigation must include the evaluation and suitability of the affected batches for market/clinical use.

7.3.5 Complete investigations of the deviation within 30 (thirty) working days.

NOTE:

Ø Head

of Quality Assurance or His / Her Nominee must be notified of all

Investigations that are open beyond 10 (ten) working days.

Ø Investigations

that exceed 10 (ten) working days must be justified and include action plans

with time commitments.

7.4 Closure, Archiving and Trend Analysis

7.4.1 Detect the recurrent problems.

7.4.2 Implement corrective action or preventative action, if any.

7.4.3 Update the deviation logbook.

7.4.4 Sign the section 8 of Annexure-III with decision and remark to close the deviation report.

7.4.5 Send the completed deviation report and accompanying documents (if any) to Officer /Sr. Officer QA for archival at the deviation file.

7.4.6 Send the photocopy of the completed deviation report to the Department from where the deviation is raised and also attach a copy with the relevant batch manufacturing record.

7.4.7 Include a summary of all deviation in the annual report for trend analysis.

NOTE:

Ø In

the event of Out of Specification (OOS) or A typical laboratory results the investigation

must follow the relevant SOP - Evaluation of Analytical Test Result and

Investigation of Out Of Specification Test Result (OOS)

Ø The

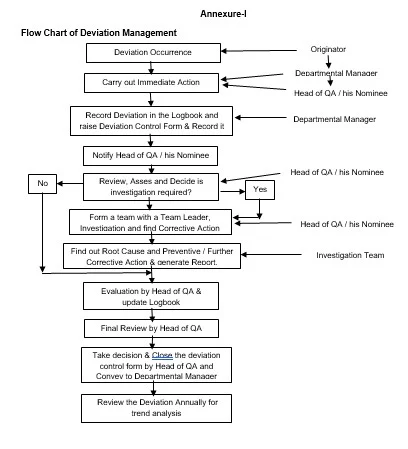

procedure is illustrated as a flow chart in Annexure-I.

7.5 Content of Deviation Management Form (Annexure-III)

7.5.1 Section 1:

Originating Department - Name of the

originating department raising deviation form

Date – Date of raising deviation form

Date of Incident - Date of deviation

occurrence

Incident Batch Linked - Yes / No (tick

which is appropriate)

Batches Affected – Batch Nos. of the

products that are affected.

7.5.2

Section

2:

Product

Name - Name the product for which deviation is raised

Batch

Number - Deviation is raised for batch number of the product

Date of

Manufacturing - Date of manufacturing of the mentioned product / material

Date of Expiry - Date of expiry of the

mentioned product / material

Supplied

Material - Name the supplied material for which deviation is raised

Supplier

Lot Number - Deviation is raised for lot number of the supplied material

Quantity -

Quantity of the batch affected / supplied material

Process –

Name of the process for which deviation is raised

Machine -

Name of the machine for which deviation is raised

System - Name of the system for which

deviation is raised

7.5.3

Section

3:

Deviation (detailed description of the deviation, if

required use extra page) - Originator will write up the incident of deviation

and also write up his name, signature and date.

7.5.4

Section

4:

Immediate

Corrective Action – Mention the decision that was taken an immediate corrective

action by originator and departmental manager in consultation with Head of

Quality Assurance or His / Her Nominee to make the process / product / system /

material secure, to prevent further deterioration. Departmental Manager will

write up the Immediate Corrective Action with signature and collect signature

from the above person mentioned.

7.5.5

Section

5:

Investigation

(if required) and Corrective Action (attach any additional information on a

separate sheet) - Investigation Team Leader will write up the Investigation

Report and Corrective Action with signature and collect signature from Head of

Quality Assurance or His / Her Nominee.

7.5.6

Section

6:

Possible

Root Cause and Preventive Action - Investigation Team Leader will write up the

Possible Root Cause and Preventive Action in consultation with Head of Quality

Assurance or His / Her Nominee with signature. Mention the preventive Action

with the person responsible for and the completion date.

7.5.7

Section

7:

Evaluation

(Product Impact) - In Head of Quality Assurance or His / Her Nominee will write

down the impact of this deviation on the product (considering the investigation

report) and corrective action, root cause and preventive action with signature

and date.

7.5.8

Section

8:

Closure

- In closure the Departmental Manager in consultation with Head of Quality

Assurance or His / Her Nominee will decide to accept or reprocess or require

additional IPQA / QC test or require further validation / revalidation or

stability test or reject with signature. Mention the completion date. Other

than the above write it down at the remarks.

8.0

Reference

Document

8.1 In-house

9.0

Annexure

9.1 Annexure-I : Flow Chart of Deviation Management

9.2 Annexure-II : Format of “Logbook for Deviation Management”

9.3

Annexure-III : Deviation Management Form

10.0 Revision History

Revision No. | Brief reason for the revision | Effective Date | Remarks |

01 | New |

11.0

Training

11.1 Head of Quality Assurance or his nominee

give the training of production operator and worker.

Annexure-III

Deviation

Control Form

Section 1 Section 2

|

Originating

Department: |

Product

Name: |

|

Batch No.: |

|

|

Date: |

Date of

Mfg.:

Date of Exp.: |

|

Supplied

Material: |

|

|

Date of Incident: |

Supplier

Lot No.: |

|

Quantity: |

|

|

Incident

Batch Linked: Š Yes / ŠNo |

Process:

|

|

Batches

Affected: |

Machine: |

|

System: |

Section 3

|

Deviation (detailed

description of the deviation, if required use extra page)

Originator’s Name:

Signature: Date: |

Section 4

|

Immediate Corrective Action

(Departmental Manager) (Sr. /Officer QA ) / (Head of QA) |

Section 5

|

Investigation

(if required) & Corrective Action (attach any additional information on a

separate sheet)

(Investigation Team Leader) (Sr. /Officer QA ) / (Head of QA) |

Section 6

|

Possible

Root Cause

Preventive Action |

||

|

Action |

Responsibility |

Completion Date |

|

|

|

|

|

(Investigation Team Leader) (Sr. /Officer QA ) / (Head of QA) |

||

Section 7

|

Evaluation

– Product Impact

(Sr. /Officer QA ) / (Head of QA) |

Section 8

|

Closure (Tick the

following): |

|||||

|

Accept |

Reprocess |

Additional

QA/QC

Test |

Further

Validation/ Revalidation |

Stability

Test |

Reject |

|

Completion

Date: Remarks

(Departmental Manager) (Sr. /Officer QA ) / (Head of QA) |

|||||