1.0 Purpose

1.1 To lay down a procedure for operation and cleaning of Auger filler machine.

2.0 Scope

2.1 This procedure is applicable for Auger filler machine of production area at “NAME” Pharmaceuticals Ltd.

3.0 Responsibility

3.1. Only concern operator is responsible for normal operation. He/ She inform the supervisor about any deviation from

normal operation. He also maintains log book.

3.2. Sr. Officer- Production/Officer- Production is responsible for monitoring day to day activity.

3.3 Production and Quality Assurance Officer shall ensure that the procedure is implemented properly.

4.0 Abbreviations and Definitions

4.1

None

5.0 Materials and Equipment

5.1

Lint free cloth

5.2

Tap /portable water

5.3 Purified water

5.4 Detergent Solution / Cleaning agent : 0.4% (w/v) Sodium Lauryl Sulphate solution ; 4 gm Sodium lauryl

Sulphate is dissolved in 1.0 liter of portable / tap water to prepare detergent solution.

5.5 70 % Isopropyl Alcohol

6.0 Precaution / Health and Safety Considerations

6.1

Before starting the machine

fill gearbox with oil and check on lubricant point.

6.2

During the maintenance,

Servicing and cleaning always press emergency stop.

6.3

Never try to clean while the

machine is in running.

7.0 Procedure

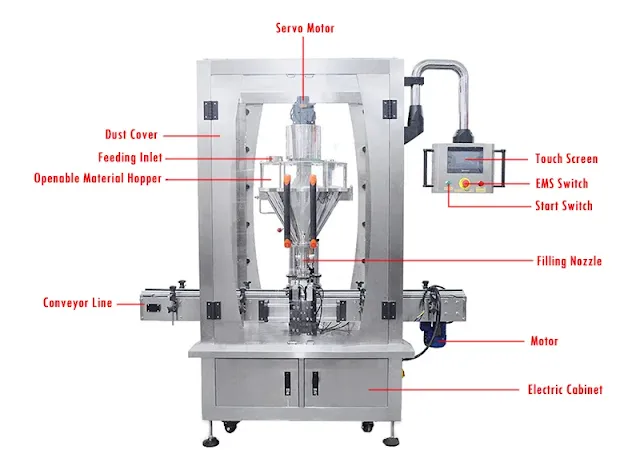

7.1 Operation procedure

7.1.1 Before starting operation, the operators and the personnel with this operation must ensure that the Room is properly cleaned and all materials of previous product are removed.

7.1.2 Production person get the line clearance from QA person and affix the status label with Product Name, batch details to equipment.

7.1.3 Switch on the main switch / power.

7.1.4 Load / charge the hopper with powder.

7.1.5 Switch on the auger motor and keep the feeder motor feed rate knob in full, make sure that there is a bottle filling

nozzle. Turn the fill switch from off to feed position.

7.1.6 Now the feeder motor operates at full speed and transfers the powder from hopper to fill cylinder.

7.1.7 Set the weight control and set the machine to work at a slow speed and at a small quantity of fill weight.

7.1.8 Take 10 filled bottles and switch off the fill switch, weight the content of the bottle to evaluate the fill accuracy

of the machine.

7.1.9 Under proper setting of all controls and sensors the operator can operate the machine with confidence about the

accuracy of the filled weight.

7.1.10 After completion the operation, to stop the machine.

7.1.11 Affix the “To be Cleaned” label and keep the record in Machine Logbook (Annexure-I).

7.2 Cleaning

7.2.1 Batch to Batch Cleaning

7.2.1.1 Remove

the filling nozzle, the auger filler and the filling cylinder.

7.2.1.2 Clean

all the above parts with clean lint free cloth.

7.2.1.3 Clean

the SS table and the machine body.

7.2.1.4 Using a vacuum cleaner to clean the

machine body and hopper.

7.2.1.5 Clean

the room as per Room Cleaning SOP.

7.2.1.6 Fix

the “Cleaning Certificate” which indicates the product name, Batch No etc.

7.2.2 Product Change Over

7.2.2.1 Using

a vacuum cleaner to clean the machine body and hopper.

7.2.2.2 Remove

the powder filler hopper, the filling cylinder, the auger filler and the powder

filling nozzle.

7.2.2.3 Clean all the above parts as well as the feeding plate / base plate, SS table, the shaft with wet cloth and detergent

solution.

7.2.2.4 Rinse

with purified water and wipe all the parts with clean lint free dry cloth.

7.2.2.5 Wipe

all the parts with clean lint free cloth and 70 % Isopropyl Alcohol.

7.2.2.6 Clean

the room as per Room Cleaning SOP.

7.2.2.7 Machine

operator / worker will request Production Officer and QA Officer for checking

visual inspection.

7.2.2.8 At first Production Officer will check the machine and its surroundings, then QA Officer will check the machine

and its surroundings. If it found satisfactory result, then he / she will issue “Cleaning Certificate” label and give

initial in respective room logbook.

7.2.2.9 Record in Machine logbook (Annexure-I) and affix the “Cleaning Certificate” label on the machine.

7.2.2.10

After cleaning the machine if it remains

without operation for next 72 hour, will undergo Re-cleaning operation.

8.0 Reference Document

8.1 In-house

9.0 Annexure

9.1 Annexure- I : Format of Machine Logbook

10.0 Revision History

|

Version No. |

Brief reason for the revision |

Effective Date |

Remarks |

|

01 |

New |

|

|

11.0 Training

11.1 Head of Production

or his nominee give the training of production operator and worker.