1.0

Purpose

1.1 To define a standard operating and cleaning procedure of Liquid Filter Press.

2.0 Scope

2.1 This procedure is applicable for Liquid Filter Press in liquid production area of “NAME” Pharmaceuticals Ltd.

3.0 Responsibility

3.1. Only trained operator is responsible for normal operation. He/ She inform the supervisor about any deviation from normal operation. He also maintains logbook.

3.2. Sr. Officer- Production/Officer- Production is responsible for monitoring day to day activity.

4.0 Abbreviations and Definitions

4.1 None

5.0 Materials

and Equipment

5.1 Nylon Scrubber

5.2 Lint free cloth

5.3 Detergent Solution, 0.4% (w/v) Sodium

lauryl Sulphate: 4 gm Sodium lauryl

Sulphate is dissolved in 1.0 liter

of portable / tap water to prepare detergent solution.

6.0 Precaution / Health and Safety Considerations

6.1 Don’t press electric switch with wet hand.

6.2 Ensure the surrounding areas are cleaned before starting operation.

6.3 Before set the filter cloth; soak it in purified water.

7.0 Procedure

7.1 Operation Procedure

7.1.1 Check that all parts are clean and dry.

7.1.2 Affix the “Operation Status” label.

7.1.3 Fit S.S. Plate, frame, filter cloth in

correct way and correct position, arrange them in filter chamber, fit the screw and tighten the lid

screw as follows:

Ø Filter

press consists of 10 sets of filter plates, sieves and filter cloth.

Ø Place

one set of filter disc (SS plate, sieve, filter cloth, filter plate) repeat the

same for all 10 sets.

Ø They

are fitted with 4 long bolts and this assembly is fitted in to the chamber

along with long bolt in the center.

Ø Placed

the center rod in proper position and tighten. Tighten the side supporting rods

and center rod simultaneously.

Ø Place

the rubber gasket properly, so that there is no leakage when tightened up in

the assembly.

Ø Close

the lid and tighten it properly with side clamps.

7.1.4 Connect the filter press with storage tank outlet valve with required length of clean, dry flexible hose pipe.

7.1.5 Open the valve of storage tank and filter

press.

7.1.6 Switch on power supply and start filter

press pump.

7.1.7 Keep air vent valve open initially, when

solution start to come out close air vent valve. Solution starts to come out from the assembly. Take

approximately 100 ml in glass beaker to check

clarity of solution. If not satisfactory reset filter assembly and again start

filtration.

7.1.9 Maintain records of Liquid Filter Press Logbook.

7.2 Cleaning

Procedure:

7.2.1 Ensure all the material is removed from

the equipment.

7.2.2 Remove the product status label and affix

“To Be Cleaned” label.

7.2.3 Spray potable water on the outer

surface of the filter press to remove the adhered material.

7.2.4 Open

lid of filter assembly, unscrew the filter assembly and pullout whole assembly.

Dismantle the plate and frame

unit, filter cloth/ pad.

7.2.5 Clean

the filter cloth with detergent solution (0.4% w/v sodium lauryl sulphate) and

finally wash with purified

water. Then dry the filter cloth by dryer keep in clean poly bag.

7.2.6 Clean

the Dismantle part with potable water then detergent solution (0.4% w/v sodium

lauryl sulphate) and finally wash with purified

water.

7.2.7 Assemble

the filter press without filter cloth.

7.2.8 Take

150 Liter hot purified water (75⁰c) in SS container.

7.2.9 Connect

the filter press to SS container, start recirculation for 10 minutes, drain it.

7.2.10 Dismantle

the filter press again and wipe the inner and outer surface with dry lint free

cloth.

7.2.11 Reassembly

the filter press with clean cloth.

7.2.12 Before machine operation, it is mandatory

to run machine with hot purified water (75⁰ C) at least 10

minutes.

7.3 Machine operator / worker will request

Production Officer and QA Officer for checking visual

inspection.

7.4 At first Production Officer will check

the filter press and its surroundings, and then QA Officer will check the filter press and its

surroundings. If it found satisfactory result, then he / she will issue “Cleaned” label.

7. 5 Record in Liquid filter press logbook and attach

the label of “Cleaned” in the machine.

7.7 After

cleaning the filter press if it remains without operation for next 72 hour,

will undergo re-cleaning

operation.

8.0 Reference Document

8.1 In House

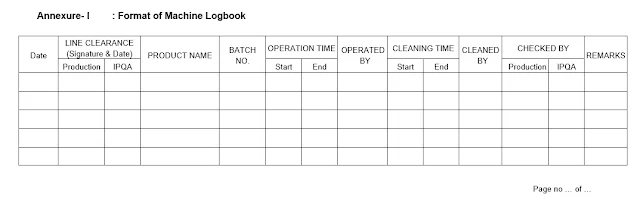

9.0 Annexure

9.1 Annexure- I : Format of Machine Logbook

10.0 Revision History

|

Revision

No. |

Brief reason for the revision |

Effective Date |

Remarks |

|

01 |

New |

|

|

11.0 Training

11.1 Head of Production or his nominee give the training of production operator and worker.

.jpeg)