1.0

Purpose:

1.1 To establish a formal procedure for the bacterial endotoxin

test procedure of Raw Material and Finished Product.

2.0

Scope:

2.1 This

SOP applies to Microbiological Laboratory.

3.0

Responsibilities:

3.1

Officer (Microbiology) is responsible for

performing the Bacterial Endotoxin test.

3.2 The Head of Quality Control/In-Charge is responsible for the compliance of this SOP.

3.3 Head of QA is responsible for SOP compliance.

4.0

Abbreviations

and Definitions

4.1 BET : Bacterial Endotoxin Test

4.2 CSE : Control Standard Endotoxin

4.3

MVD :

Maximum Valid Dilution

4.4

LRW :

Lal Reagent Water

4.5

PPC

:

Positive Product Control

4.6

NPC :

Negative Product Control

4.7

PWC :

Positive Water Control

4.8

NWC :

Negative water control

5.0

Materials

and Equipment

5.1 Equipment’s required:

5.1.1 LAFU

5.1.2 Incubator

5.1.3 Vortex mixture

5.1.4 Micropipettes

5.2 Material Required:

5.2.1 CSE

5.2.2 Lysate

5.2.3 LRW

5.2.4 Depyrogenated dilution tube

5.2.5 Depyrogenated assay tube

5.2.6 Sterile, endotoxin free micro tips

6.0 Precaution / Health and Safety Considerations

6.1 Ensure the depyrogenation of all glassware.

6.2 Ensure plastic apparatus are free of detectable Endotoxin or interfering effects of the test.

6.3 Always use fresh reconstituted lysate.

6.4 Rehydrated CSE may be stored for 28 days at 2 to 8°C.

6.5 Do not vortex lysate.

7.0

Procedure:

7.1

General:

7.1.1

Clean all the required glassware’s and depyrogenate at

220° C for 1.5 hours.

7.1.2

Transfer all the depyrogenated glassware’s to

microbiology lab.

7.1.3

Switch “ON” the Incubator and set the temperature at

37°C.

7.1.4

Calculate MVD of the product by following formula –

|

MVD = |

Endotoxin Limit X Product

Concentration |

|

Lysate

Sensitivity |

7.1.5

Prepare the sample according to its product

concentration.

7.1.6

Dilute the sample to be tested to its half MVD with

LRW and shake properly 3 minute on vortex mixer for.

7.2

Preparation Of Control Standard Endotoxin (CSE):

7.2.1 Reconstitute CSE in LRW as per manufacturer

instruction and vortex for 5 - 10 minutes.

7.2.2

Use Reconstituted CSE within 4 weeks after

reconstitutions. Store reconstituted CSE at 2°C to 8°C

temperature.

7.2.3

Prepare a CSE dilution with LRW to get 1 EU/ml and

vortex for 5 minutes.

7.2.4

Prepare a 4λ by diluting from 1 EU/ml with LRW and

vortex for 5 minutes (4λ to be back calculated from λ where λ is the Lysate

sensitivity).

7.3

Reconstitution of Lysate:

7.3.1

Reconstitute the lysate

after opening the aluminium seal of lysate.

7.3.2 Loosen lysate powder into

the bottom of the vial by tapping on a hard surface and then open the cork

slowly.

7.3.3 As per manufacturer’s

instruction, reconstitute with LRW before use and replace the cork immediately.

7.4

Confirmation of the Labelled Lysate Sensitivity:

7.4.1

Confirm in four replicates the labelled sensitivity λ, expressed in

EU/ml or IU/ml, of the lysate solution prior to use in the test. Confirmation

of the lysate sensitivity must be carried out when a new batch of lysate is

used or when there is any change in the experimental conditions which may

affect the outcome of the test.

7.4.2

Prepare

CSE dilutions from 4λ

solutions of at least four concentrations equivalent to 2λ, λ,

0.5λ and 0. 25λ by diluting a series of CSE solution with water for

BET (LRW).

7.4.3 Take

10 depyrogenated assay tubes and label the tubes by numbering and arrange

quadruplicate in stand and the proceed as per following Table - 1

Table - 1

|

Sample

|

CSE

dilution

used |

LRW |

Lysate in µl |

No.

Of replicates |

|

2 λ |

100µl |

- |

100 µl |

4 |

|

λ |

100 µl |

- |

100 µl |

4 |

|

0.5

λ |

100 µl |

- |

100 µl |

4 |

|

0.25

λ |

100 µl |

- |

100 µl |

4 |

|

NWC |

- |

100 µl |

100 µl |

4 |

7.4.4 Pipette 100 µl diluted CSE i.e. to 2λ, λ, 0.5λ, and 0.25λ separately into depyrogenated borosilicate test tubes (10 mm X 75 mm) and labeled accordingly. For NWC (negative water control) use 100 µl LRW separately and perform the test in quadruplicate.

7.4.5

Add

100 µl of reconstituted Lysate into each tube and mix gently.

7.4.6

Incubate

the reaction mixture for a constant period at 37° c± 1° c for 60 ± 2 minutes,

avoiding vibration.

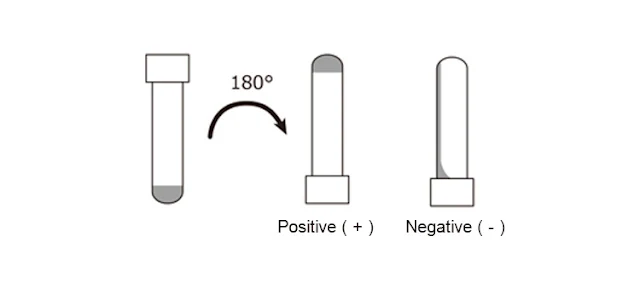

7.4.7 After

incubation, take each tube and turn directly from the incubator and invert it

through approximately 180° in one smooth motion. If a firm gel has formed that

remains in place upon inversion, record the result as positive. A result is

negative if an intact gel is not formed.

7.4.8

The

test is not valid unless the lowest concentration of the standard solutions

shows a negative result in all replicate tests.

7.4.9

The

endpoint is the last positive result in the series of decreasing concentrations

of endotoxin. Calculate the mean value of the logarithms of the end-point

concentrations and then the antilogarithm of the mean value using the following

expression:

7.4.10

The geometric

mean end-point concentration is the measured sensitivity of the lysate solution

(EU/ml or IU/ml). If this is not less than 0.5 λ and not more than 2 λ, the

labelled sensitivity is confirmed and is used in the tests performed with this

Lysate.

7.4.11

Test

Procedure:

7.4.12

Prepare

solutions A, B, C and D as shown in Table 2

Table – 2

|

Solution |

Solution description |

LRW in

µl |

42λ (CSE) in µl |

Product at MVD/2 in µl |

Lysate in µl |

No. of Replicates |

|

A |

Negative product control (NPC) |

50 |

- |

50 |

100 |

2 |

|

B |

Positive Product

control (PPC) |

- |

50 |

50 |

100 |

2 |

|

C |

Positive water

control (PWC) |

50 |

50 |

- |

100 |

2 |

|

D |

Negative water

control (NWC) |

100 |

- |

- |

100 |

2 |

7.4.13

Take 8

depyrogenated assay tubes and label the tubes by numbering and arrange in stand

one opposite to each other. i.e. 1 & 2 for NPC, 3 & 4 for PPC, 5 &

6 for PWC, 7 & 8 for Negative water control.

7.4.14

Add 50µl

of LRW in PPC and PWC, and 100 µl in NWC. Immediately add 50 µl of product

sample, which is diluted at MVD/2 in a NPC and PPC, and then add 50µl of CSE

that is diluted to 4λ in a PPC and PWC.

7.4.15 Finally add 100µl of Lysate in all tubes and next, mix the assay tubes by hand and incubate in heating block, where the temperature is maintained at 37°C ± 1°C for 60 ± 2 minutes.

Flow

Sheet: This diagram illustrates the testing procedure of LAL test.

7.4.16 Reactive

Test: Take 100μl dilulated sample (as indicated) and then take 100μl LAL (0.125EU/ml) reagent into LAL test tube.

7.5

Interpretation of Result:

7.5.1

Each

tube in the gel clot method is interpreted as either positive or negative,

Positive test indicates the formation of firm gel capable of maintaining its

integrity when the test tube is inverted 180°.

7.5.2

A

negative test is characterized by the absence of gel or by the formation of a

viscous mass, which does not hold when the tube is inverted at 180°.

7.5.3

The

test is not valid unless both replicates of the two positive control solutions

B and C are positive and those of the negative control solution D are negative.

7.5.4

The preparation being examined complies with the test

when a negative result is found for both replicates of solution A.

7.5.5

When

a positive result is found for both replicates of solution A, it does not

comply with the test.

7.5.6

Repeat

the test if a positive result is found for one replicate of solution A and a

negative result is found for the other. The preparation being examined complies

with the test if a negative result is found for both replicates of solution A

in the repeat test.

7.6

Failure Investigation:

7.6.1

When

positive result observed on both the tubes of test preparation, investigate the

cause of its failure by checking following parameters.

7.6.2

Check

product dilution, CSE dilution and lysate dilution.

7.6.3 Whether

Glassware’s are cleaned and dehydrogenated as per standard Operating procedure.

7.6.4

Check

sensitivity report of Lysate lot and matched CSE.

7.6.5

Check

Incubator temperature and calibration.

7.6.6

Check

Micropipette calibration.

7.6.7

Check

any source of contamination occur due to microbiologist.

8.0 Reference Document

8.1

USP <85>

9.0 Annexure

9.1

Annexure-I: Bacterial

Endotoxin Test Report

10.0

Revision

History

|

Revision

No. |

Brief reason for the revision |

Effective Date |

Remarks |

|

01 |

New |

|

|

11.0

Training

11.1

Head of Quality Control or his/her

nominee shall give the SOP training before effective date.