1.0 Purpose

1.1 To lay down a procedure for cleaning of dispensing booth and area during every product change over.

2.0 Scope

2.1 This SOP shall be Applicable cleaning of

Dispensing booth and area during every product change

over at Dispensing Department in NAME Pharmaceuticals Ltd.

3.0 Responsibility

3.1 The concerned store person and section cleaner

shall follow the cleaning procedure as per this

SOP

3.2 Officer-Store or Store In-Charge is

responsible to execution of this SOP.

4.0 Abbreviations and Definitions

4.1 Disinfectant Solution: Solution used to make free from microorganism.

Savlon Solution (5% v/v) :50 ml is mixed with 1.0 liter of tap / portable water to prepare disinfectant solution. or

Dettol Solution (2.5% v/v): 25 ml is mixed with 1.0 liter of tap / portable water to prepare disinfectant solution.

4.2 70 % Isopropyl alcohol: 30 ml water in 70 ml Isopropyl alcohol

of 100 % concentration.

5.0 Materials and Equipment

5.1 Ensure following Cleaning Equipment/

Tools/ Agent are used in order to clean.

5.1.1 Portable Vacuum Cleaner

5.1.2 Lint Free Cloth

5.1.3 Mop

5.1.4 Nylon Scrubber,

5.1.5 SS tray or Container

5.1.6 Potable Water

5.1.7 Purified Water

5.1.8 Disinfectant solution: Savlon

Solution (5% v/v) or Dettol Solution (2.5% v/v)

5.1.9 Isopropyl Alcohol Solution (70%)

3.1.10 Rubber hand gloves

6.0 Precaution / Health and Safety Considerations

6.1 Person

carrying out filter cleaning activity should wear following apparel:

Ø Clean apron and cap

Ø Nose mask

Ø Rubber hand gloves

7.0 Procedure

7.1 Procedure

for Cleaning of Dispensing Tools

7.1.1 After complete dispensing of raw material for a product, all dispensing tools shall be collected in the container or SS Tray or polythene bag having status label “To Be Cleaned” and transfer to washing area.

7.1.2 All dispensing tools shall be washed with running purified water by scrubbing with nylon scrubber, sanitize with 70% v/v Isopropyl Alcohol (IPA) and dry it by using clean dry Lint Free Cloth.

7.1.3 All dispensing tools shall be kept in clean polythene bag and placed in clean and dry HPDE container / plastic drum with “Cleaned” Label

7.1.4 Cleaning of dispensing tools shall be recorded in Cleaning Record for Dispensing Area and Dispensing Tools.

7.1.5 Use the cleaned tools within 72 hours. If not used, then again clean the tools before use as per the above procedure.

7.2 Procedure for Cleaning of Filter.

7.2.1 Check the electric supply of RLAF is switched-off.

7.2.2 Open the access grill of return filter by removing screw nut.

7.2.3 Removes the filters and take the filter to designated cleaning area.

7.2.4 Clean the filter from the front with the help of a vacuum cleaner.

7.2.5 Clean the filters from the backside by air under pressure. Ensure all ducts / dirt is removed completely.

7.2.6 Ensure that the filters are clean and dry.

7.2.7 Refitted the cleaned filter to the designated dispensing booth.

7.2.8 Frequency of Cleaning: Product changes over or as per required.

7.3 Procedure for Cleaning of Dispensing Booth and Area:

7.3.1 Check the electric supply of RLAF is switched-off.

7.3.2 The filter grills, SS Table and floor of the dispensing area shall be cleaned with vacuum cleaner.

7.3.3 Wipe the top to bottom SS grill, metal surfaces, plastic curtain, balances etc. with a cleaned lint free wet cloth with 70% v/v IPA.

7.3.4 Mop the entire floor with cloth wetted with disinfectant solution on rotated weekly with Dettol 2.5 % v/v and Savlon 5.0% v/v. Finally wipe entire floor with dry lint free mop.

7.3.5 Affix the “Cleaned” Label in the respective area after cleaning.

7.3.6 Frequency of Cleaning: Product changes over.

8.0

Reference Document

8.1 WHO GMP Guideline, trs-986, annex-2

8.2 In-house

9.0 Annexure

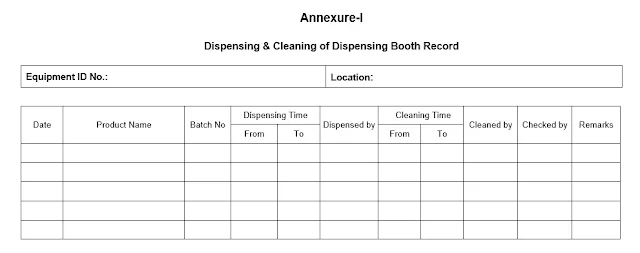

9.1 Annexure-I : Dispensing & Cleaning of Dispensing Booth Record

9.2 Annexure-II : Cleaning record for Dispensing Area and Dispensing Tools

10.0 Revision History

|

Version No. |

Brief Reason for the Revision |

Effective Date |

Remarks |

|

01. |

New |

|

- |

|

|

|

|

|

11.0 Training

11.1 Training is

required for store person and section cleaner of store, Store Officer and Store

In- charge by Head of Warehouse.